The Future of Logistics is Folded: How KraftPal’s Paper Pallets Are Disrupting a $13 Billion Market

In the vast, intricate dance of global logistics, the humble pallet is the unsung hero. It is the foundation upon which virtually every product we consume is stacked, stored, and shipped. For decades, this foundation has been built from wood—heavy, inefficient, and environmentally costly. The global supply chain moves on the back of nearly 8 billion wooden pallets, a system that contributes to deforestation, high carbon emissions, and significant operational costs. But a quiet revolution is underway, and it’s made of paper.

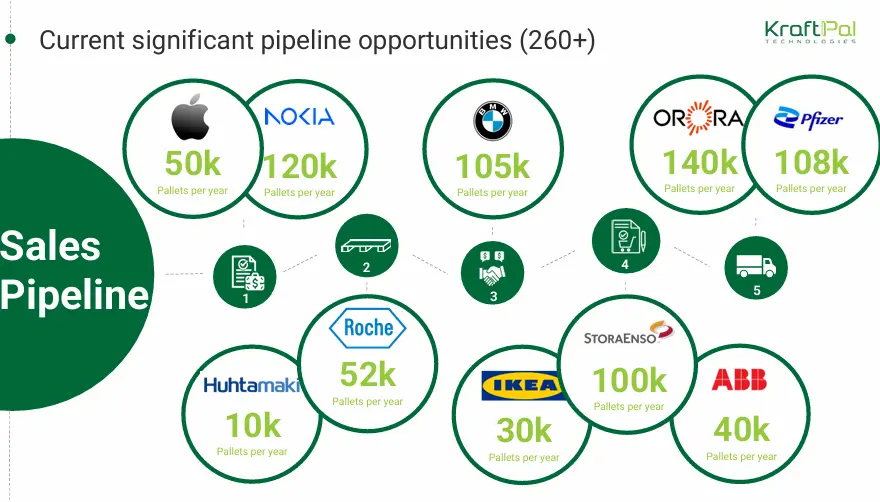

KraftPal Technologies, a pioneering firm backed by a vision for a greener and more efficient future, is challenging the status quo with a deceptively simple yet technologically advanced solution: the corrugated paper pallet. This is not just a lighter alternative; it is a complete reimagining of how goods are moved. By replacing a single, splinter-prone wooden pallet with a durable, lightweight, and fully recyclable paper one, KraftPal is not only saving trees but also unlocking massive efficiencies and cost savings for companies across the globe. With a serviceable available market of over 660 million pallets annually and a growing roster of blue-chip clients like Apple, BMW, and Pfizer, KraftPal is not just building a better pallet—it is building the future of the supply chain.

This article explores the technology, vision, and disruptive force of KraftPal, a company proving that the most powerful innovations are often the ones that are elegantly simple, profoundly impactful, and ready to change the world, one shipment at a time.

The Heavy Burden of the Wooden Pallet

The wooden pallet is so ubiquitous that its profound inefficiencies are often overlooked. The industry standard is a product born of necessity in a bygone era, and it carries a heavy environmental and economic toll. The production of nearly two billion new disposable wooden pallets each year requires the felling of millions of trees, contributing to deforestation and the loss of critical CO2-absorbing forests.

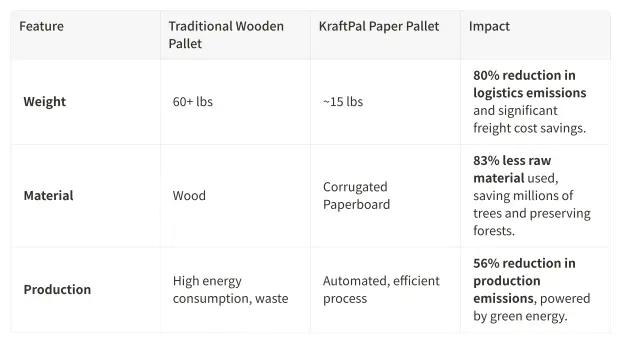

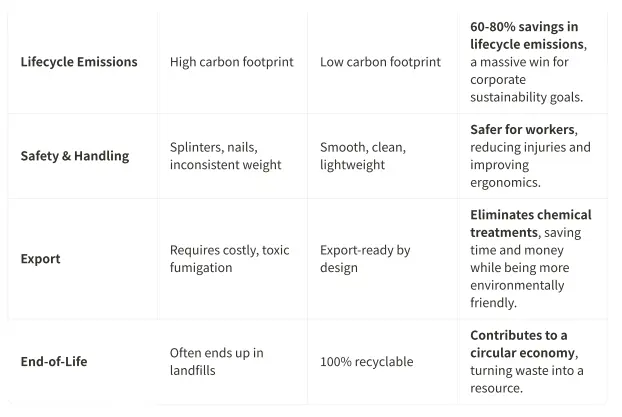

The problems continue down the supply chain. Wooden pallets are heavy, often weighing over 60 pounds, which adds significant weight to every shipment and drives up fuel consumption and logistics costs. They are prone to splintering and breaking, creating safety hazards for workers and risking damage to goods. Furthermore, for international shipping, they require expensive and toxic chemical treatments (fumigation) to prevent the spread of pests, adding another layer of cost and environmental concern.

The KraftPal Revolution: Lighter, Stronger, Smarter

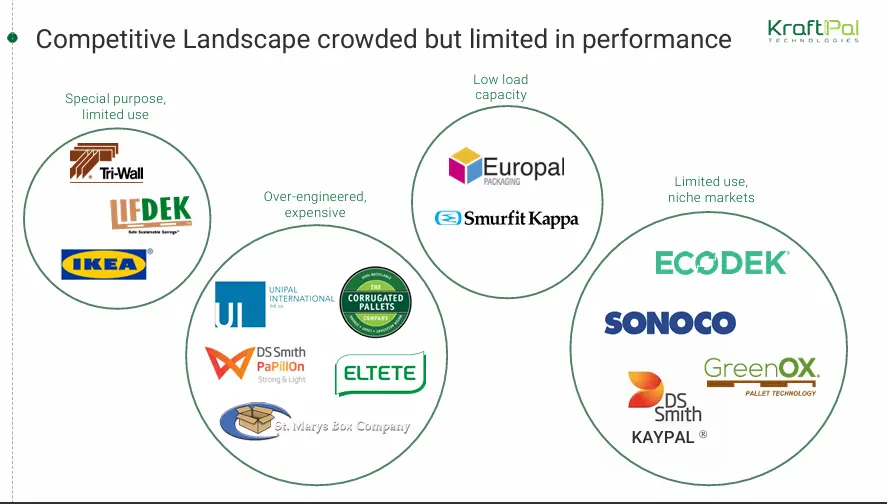

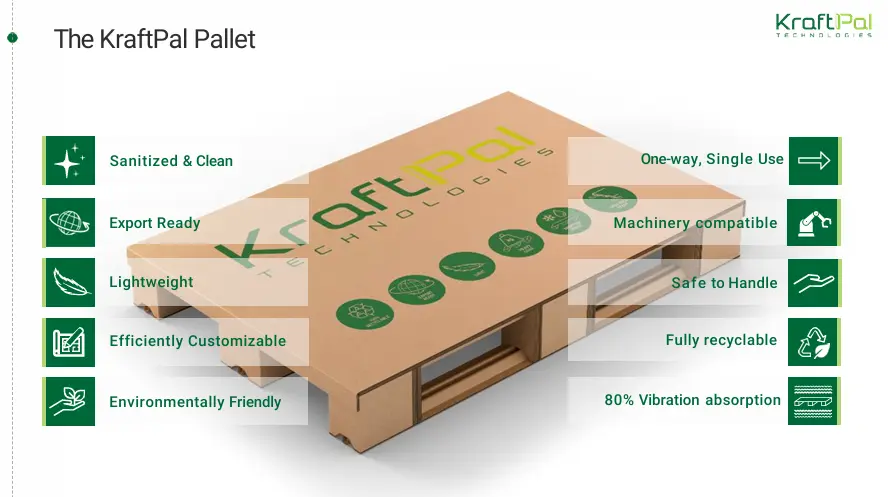

KraftPal’s solution is a masterclass in innovative design and material science. The company has engineered a corrugated paper pallet that is not only a fraction of the weight of its wooden counterpart (around 15 pounds vs. 60+ pounds) but is also remarkably durable and fully compatible with all existing automated logistics systems. This is the key differentiator that sets KraftPal apart from a crowded field of niche, low-performance paper pallet competitors.

The benefits of this shift are staggering and ripple across the entire value chain.

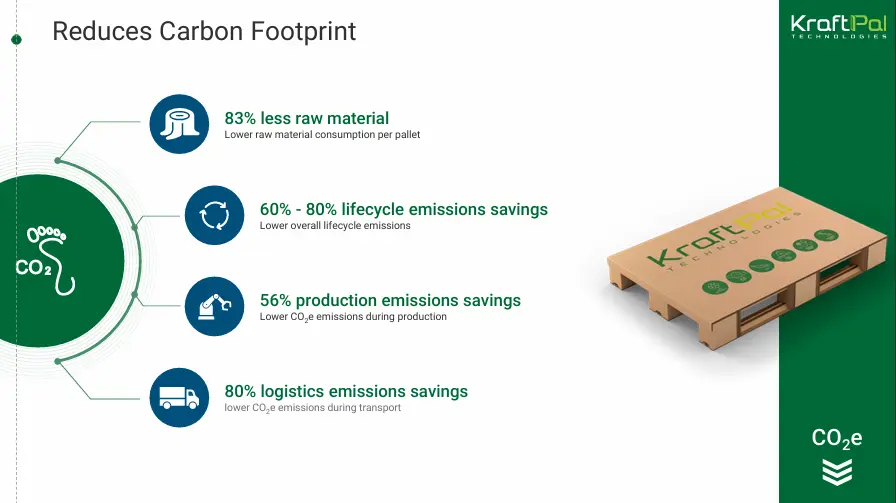

By replacing just one-third of the world’s disposable wooden pallets, KraftPal estimates it can save over 79 million trees, conserve 148,000 football fields of forest area, and prevent the emission of 4.2 million metric tons of CO2e annually. These are not just numbers; they represent a fundamental change in the environmental calculus of global trade.

The “Palletonator”: Manufacturing the Future

The genius of KraftPal extends beyond the pallet itself to its revolutionary manufacturing process. The company has developed a fully automated, Industry 4.0 production line called the “Palletonator [5000x].” This modular, robotic system is a marvel of modern engineering, capable of producing up to 240 pallets per hour with a crew of just three people.

This technology allows KraftPal to deploy Local Production Units (LPUs) quickly and efficiently anywhere in the world, manufacturing pallets on-demand and close to its customers. The Palletonator is powered by green energy sources and uses real-time data monitoring to optimize performance and minimize downtime. This lean, agile, and scalable manufacturing model is a core component of KraftPal’s competitive advantage, enabling it to meet the demands of a global market with unprecedented speed and flexibility.

This entire process, from the pallet design to the Palletonator itself, is protected by a formidable portfolio of over 28 intellectual property rights worldwide, including patents, trademarks, and design registrations. This ensures that KraftPal’s unique technology remains a defensible moat as it scales its operations.

A World-Class Team and Strategic Backing

A disruptive vision requires world-class execution, and KraftPal is led by a management team with deep global experience in technology, logistics, finance, and manufacturing. The company was founded by Gregor Brajovic, an experienced lawyer with a background in disruptive technology projects. Today, it is led by CEO Paul Williams, a global logistics veteran with extensive experience across Europe and the Asia-Pacific region. The leadership team includes former executives from giants like Apple, Siemens, and McGraw-Hill, bringing a wealth of operational and strategic expertise.

This powerhouse team is backed by Pasaca Capital, a California-based private equity firm that specializes in nurturing innovative technologies. Pasaca’s investment provides not only funding but also strategic guidance and marketing support, accelerating KraftPal’s journey from a promising startup to a global industrial force.

Global Expansion: From Austria to the World

KraftPal’s global rollout is already well underway, marked by a series of strategic milestones. Since opening its first Local Production Unit (LPU) in Austria in 2019, the company has expanded rapidly:

•2021: Launched its first licensed LPU in Saudi Arabia, tapping into the burgeoning Middle Eastern market.

•2022: Secured a significant investment from Pasaca Capital, fueling its next phase of growth.

•2024: Commenced production in a joint venture in Finland and, crucially, launched its first US-based LPU in California, marking its official entry into the North American market.

This expansion is supported by key partnerships, most notably with the Orora Group, a major distribution partner that is making KraftPal’s paper pallets accessible to companies across the United States. This partnership has been met with tremendous enthusiasm, with industry leaders hailing the KraftPal pallet as a “sustainable packaging marvel.”

The Market Has Spoken: A Pipeline of Global Giants

The ultimate validation of KraftPal’s technology comes from its customers. The company has a current sales pipeline of over 260 opportunities, with samples and pilot programs requested by a who’s who of global industry leaders. Companies like Apple, BMW, Pfizer, IKEA, Nokia, and Roche are actively exploring the integration of KraftPal pallets into their supply chains. This is not just interest; it is a clear signal that the world’s biggest companies are actively seeking sustainable, efficient, and cost-effective alternatives to the wooden pallet, and they see KraftPal as the leading solution.

Conclusion: A Paradigm Shift in a Box

KraftPal Technologies is more than just a pallet company. It is a case study in how innovative thinking, smart technology, and a commitment to sustainability can disrupt a legacy industry that has been stagnant for decades. By addressing the core weaknesses of the wooden pallet—its weight, inefficiency, and environmental cost—KraftPal has created a solution that offers a rare win-win-win: it is better for the planet, better for worker safety, and better for the bottom line.

With a proven product, a scalable and protected manufacturing process, an experienced leadership team, and a rapidly growing pipeline of the world’s most demanding customers, KraftPal is perfectly positioned to capture a significant share of the $13 billion pallet market. The future of logistics is not just about faster ships or smarter software; it’s also about redesigning the fundamental building blocks of the supply chain. And as KraftPal has proven, that future is lighter, stronger, and folded from paper.